Description:

The NPL

CaviMeter™ is the first instrument capable of measuring localised ultrasonic

cavitation (the implosion of bubbles in a liquid when a high frequency sound

wave is applied), and will transform the way in which hospitals clean medical

instruments , and the way in which manufacturers develop foodstuffs, biofuels

and pharmaceuticals, by providing a new measurement

capability.

The

CaviMeter’s key component is a novel spatially-sensitive sensor that detects

aultrasonic signals from acoustic cavitation activity in fluids. Coupled with a

bespoke electronics module, the NPL CaviMeter™, it provides a visual display of

real-time cavitation activity. The NPL CaviMeter provides a quick and simple to

use measurement solution for cleaning and sonoprocessing systems, and so is a

new and improved method of quality assurance.

Main

Features

By monitoring

the acoustic signals generated in fluids when clouds of bubbles implode under the

influence of an applied sound field, the CaviMeter identifies how much

cavitation is taking place at a given location, allowing 'hot-spots' and

'cold-spots' in cavitating systems to be identified. Manufacturers can use this

information for fine-tuning equipment to produce the ideal quantity and

distribution of cleaning or processing action.

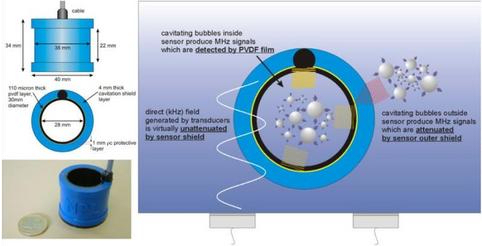

Cavitation

sensor - Two principle features of the cavitation sensor contribute make it

novel. Collapsing cavitation bubbles generate very high frequency acoustic

signals and the Sensor includes a thin piezoelectric film that responds to these

signals. The shape of the Sensor, a hollow cylinder, combined with materials of

special acoustic properties, means that the signals can be associated with

specific volumes of liquid. This gives the sensor spatial resolution, allowing

it be used to map vessels.

Applications

Provide the

first direct measurement of the driving process behind ultrasonic cleaning,

sonochemistry and sonoprocessing;

Mapping

cavitation fields in ultrasonic cleaners, sonoprocessors, cell disruptors and

therapeutic medical ultrasound devices: this enables enhanced design assessment,

manufacturing tests and user QA;

As a diagnosis

tool for fault-finding problems in cavitation-producing

systems;

As an online

monitor for cleaning and sonoprocessing systems, providing accumulated ‘dose’

information for demonstrating conformance with local standards and regulatory

requirements

Developmental Status

Working

prototype system developed and end user tested

Availability

Demonstration

of system available

IP

Status

Available for

licensing (patents in UK, Germany, USA, Japan)

Technical

Responding to

the long-term industrial need for cavitation sensors of good temporal and

spatial resolution, NPL’s cavitation sensor is designed to detect the full

acoustic spectrum produced by a cavitating cloud. Its construction and operation

are shown below:

- 30mm high, 30mm internal diameter

- Acoustic emissions from bubbles detected using thin piezoelectric

material – 110 micron thick piezoelectric polymer, pvdf, giving a bandwidth up

to 11 MHz

- 4 mm thick blue polyurethane absorbing ‘shell’, which prevents

MHz signals generated outside the cylinder from being detected by the piezo film

- Perturbation of direct field produced by vessel (kHz) minimised

by using absorber material whose acoustic impedance is matched to that of water

- The 'measure' of inertial cavitation activity is the integrated

broadband power in the frequency band 1.5 - 7 MHz, which is determined using

spectral analysis or electronic filtering

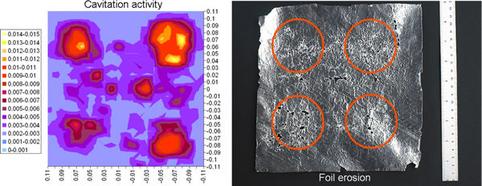

Since initial

proof-of-concept, an extensive development and testing programme has been

completed, which has shown the sensor to have a broad frequency response and

strong spatial sensitivity. Recent studies in a commercial cleaning bath show

good correlations between the cavitation activity determined by the sensor

(left) and aluminium foil erosion (right):