Description:

Remote detection of incipient cavitation (vapour/gas

filled microbubbles arising due to localised pressure extrema) in flow systems,

providing early indication of potentially damaging bubble activity, and allowing

feedback and control of pumps and valves

Main features

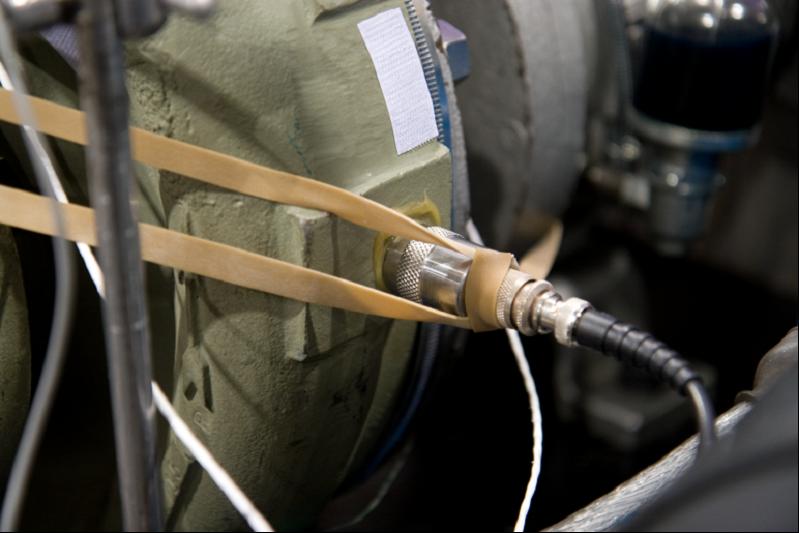

• Passive broadband detection of acoustic signals

• Simple

sensors attached remotely to flow systems – pump and valve casings etc., via

unique acoustic coupling materials

• Signal processing, filtering and

logging of data, with potential for battery operation and wireless

transmission

• Single or multiple channel operation

Applications

• Providing real-time monitoring of cavitation

to inform users on pump and flow system health, and efficacy

• As a

diagnosis tool for where, and to what extent, cavitation is occurring in

existing, proposed, and new installations

• For incorporation into flow

system controllers to optimise energy efficient and damage-free operation

•

For correlation with assessment and prediction of casing and impeller

damage

• For monitoring cavitation in turbines and other flow

systems

Developmental Status

Laboratory-scale prototype developed and

tested

Availability

Available for development and licensing

IP Status

Worldwide patent granted for detection of cavitation

in pumps by high frequency acoustic emissions

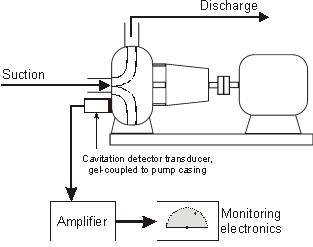

Technical

Schematic of cavitation detection

approach

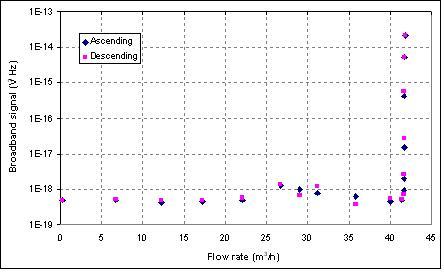

This approach has been trialled on industrial pumps –

Showing sensitive detection of cavitation

inception: